* 22 entries including: torpedoes, airliners enhance their operations, understanding crowds, rebuilding my websites, software simulation of bacterial cell, inventing materials by computer, solar power in India, "scratch-off" payment scheme for solar power in Africa, the business of AIDS, improvements in LED lighting, insecticide-laden paints, smart paints, OTEC power revisited, and DARPA works to rebuild faces.

* The US presidential race of 2012 is taking place against a backdrop of economic difficulty, a matter that both contenders have made much of. Of course, the election-year exchanges of claims and barbs have done more to obscure matters than to clarify them, with the end result of making things possibly seem more unpleasant than they really are. An editorial in THE ECONOMIST ("The Comeback Kid", 14 July 2012), made the case for optimism, backing up a cover with a buffed-up Uncle Sam with a formidable set of "pecs".

OK, first and foremost things really are not happy at present, with US unemployment above 8%, and growth likely below an annualized 2%. The government's funding problems are approach an ominous "fiscal cliff" that threatens a painful fall. However, THE ECONOMIST claims: "Old weaknesses are being remedied and new strengths discovered, with an agility that has much to teach stagnant Europe and dirigiste Asia."

America's economic difficulties did not come out of nowhere. Up to 2008, the country's growth was based too heavily on consumer spending and house-buying, both funded by foreign investment being funneled through a weak US financial system. Household debt was 100% of income in 2000; it was 133% in 2007. The bust of the system meant that households and banks would take years to repair their balance sheets.

Much of the repair has taken place. America's houses are now undervalued, and under prodding by the Treasury and other regulators US banks have been efficient, at least in comparison to their counterparts in the Euro zone, in cutting loose their bad debts -- a painful process, but one that allows them to move forward. Household debt has fallen to 114% of income, not good but in the right direction.

The USA is also enjoying more success in exports. One reason is a weaker dollar, which has done much to help reduce the trade deficit from 6% of GDP in 2006 to about 4%. That's not all of the story in exports -- one other big boost being rising demand for American goods in developing countries. There's been a lot of complaint in the USA about Chinese economic competition, but today China is the third biggest market for American exports. Some of the exports, such as Boeing jetliners, Microsoft software, and Hollywood films, are not news, but also there's an ongoing boom in high-value services -- architecture, engineering and finance -- and an "app economy" that is giving global presence to a lot of little US firms.

With improvements in manufacturing automation such as 3D printing, there's also potential shift back towards "made in the USA". Ironically, the burden of high global oil prices has had a big silver lining for the USA, improving efficiency while driving the exploitation of shale gas. Even ten years ago, it would seem hard to believe that the US would become a net exporter of fuels, but that's where American natural gas production is going.

That's all good news for whoever wins in November, but it also underlines the need for presidential judgement. One problem the winner will have to deal with is the fiscal mess, pushing through cuts plus tax increases -- Americans scream about taxes, but cuts alone just won't do the job, and it's an irresponsible fraud to claim otherwise. Another is to fix public services -- to repair dilapidated infrastructure, get the world's most expensive health-care system on the right track, improve schools, and clean up the tangle in immigration law that keeps out helping hands that the USA needs. The last four years have been dismal; to chase away the clouds in the next four years is going to demand vision and discipline.

* At the beginning of July, the European Union began a complete oil embargo against Iran. As reported by BBC.com, the Iranians had been preparing for this move, the National Iranian Tanker Company (NITC) having been changing the names of its tankers and the flags they fly. The little Pacific island nation of Tuvalu appears to be a popular choice; any member of the International Maritime Organization (IMO) can be used. Iranian tankers have also been turning off their identification transponders.

European refineries are no longer handling Iranian crude, but there are still loopholes. Tankers too big to fit through the Suez Canal pipe their loads from Ain Sukha on Egypt's Red Sea coast, with the output of the pipeline loaded onto a tanker in Alexandria; it could be tricky to figure out where the crude came from. In the meantime the Iranians are continuing to pump crude, leading to the problem of where to put it all since it's not selling very well at present. There's a rush effort to build up new storage facilities, but for the moment the Iranians have put most of their tanker fleet at anchor to be used as a temporary storage facility.

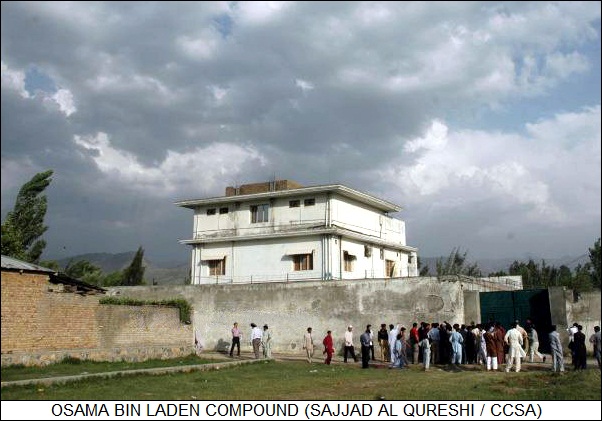

* Back in May, THE ECONOMIST's defense blogger, Clausewitz, ran a note I missed then on the release of 17 documents from a haul of intelligence material obtained in the 2011 raid on Osama bin Laden's Abbottabad compound in which the al-Qaeda leader was gunned down. The papers present Osama as deeply frustrated, having seen many of his old colleagues killed; unable to think of how to exploit the "Arab Spring" uprisings across the Mideast; lacking influence over al-Qaeda "franchises" in Yemen and the Maghreb; and no longer able to mount serious terrorist operations.

However, the papers -- issued by the Combating Terrorism Center at the US Army's West Point military academy in New York state -- were obviously carefully selected from the boxes of material seized by American SEAL commandos. If the conspiracy theorist notion of a hidden government that keeps the public hoodwinked with misinformation is a fantasy, the government clearly still has its agendas, and they are visible in this case. The documents show al-Qaeda as a decrepit organization in terminal decline, which not only helps to undermine al-Qaeda's credibility, but also to highlight the success of the US government's actions against the terror network. The documents also do everything to leave al-Qaeda guessing about how much the Americans really know about their operations, and are careful to say nothing about any official Pakistani support of Osama in his six years of residence at Abbottabad. Very few honestly believe that nobody in Pakistan's government knew Osama was living in the country.

Even given the selectivity of the documents, there's no reason to think them fabrications, and they do have their revelations. One of the most interesting is that Osama had become angry over al-Qaeda attacks on Muslims, calling for restraint on such actions and a refocus on the West, particularly America, as the proper target. There wasn't much he could really do to change matters; having chosen violence as his solution, Osama could never really recognize that violence was the solution that, by its nature, he might not be able to control as he desired. Violence has an ugly mind of its own.

COMMENT ON ARTICLE* GO WITH THE CROWD (2): Confronted with the difficulties of modeling pedestrian traffic when the pedestrians have minds of their own, researchers such as Medhi Moussaid have been coming up with models in which pedestrians are seen not as particles but instead as "agents", each of which is observing and responding to its own immediate environment -- a concept discussed here in 2009.

The approach appears to be paying off. One of the important applications of pedestrian modeling is, of course, evacuations, with one of the events that led to modeling pedestrians being a fire in the King's Cross station of the London Underground in 1987, in which 31 people were killed. One of the big dangers in an evacuation is that people will not be aware of alternate exits and will follow others trying to cram into the same exit, with disastrous results.

Particle-base models suggest that the way to deal with the problem is, counter-intuitively, to place an obstacle such as a pillar in front of an exit, splitting traffic into more efficient lanes. That's too counterintuitive for most planners, who find the idea of putting an obstacle in front of an emergency exit perverse. Moussaid believes from his work on cognitive models that a better approach would be to have lighting systems guide pedestrians to appropriate exits, darkening paths that go nowhere and lighting up the paths that people should take.

The cognitive approach falls down in the densest and most chaotic crowds, when pedestrians no longer have control over their movements, being jostled and pushed around, struggling just to stay upright. Nobody's been able to figure out a good way to resolve such a nightmare scenario, so the usual approach is to figure out how to avoid it in the first place. Engineering firms now routinely simulate the movement of people to try to spot areas where crowding is likely to occur, with simulations performed for everything from the London Olympics to the design of new railroad stations. Off-the-shelf software is available to examine likely traffic flows and chokepoints, with the software permitting simulations to compare different traffic system layouts.

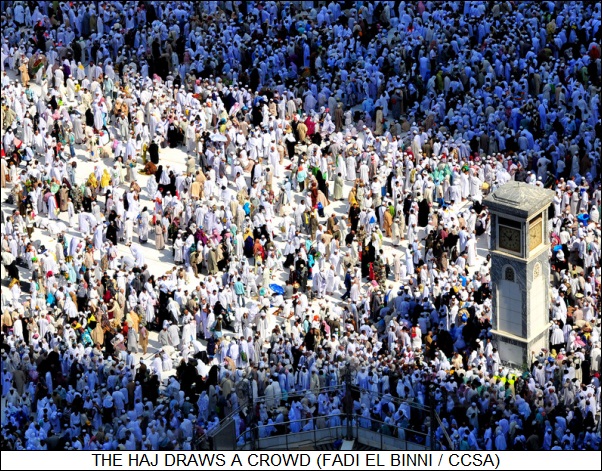

One of the biggest challenges to pedestrian modeling is the "haj", the pilgrimage to Mecca in Saudi Arabia that Muslims are expected to make once in their lives if they can. Millions of people converge on Mecca every year, creating a horrendous problem in crowd control, with a long history of crowd stampedes and deaths. Saudi authorities have brought in consultants in recent years, focusing in particular on the layout of the Jamarat Bridge, where pilgrims perform a ritual in which they throw stones at three pillars. By making the crossing one-way, and changing the shape of the pillars so that people can stone them from a number of locations, they have improved the bridge's safety.

Researchers suggest that other measures might be taken, for example installing gates to regulate the flow of foot traffic. However, the haj has some difficulties beyond its sheer scale. One is that it's very hard to predict how many people will show up each year, and techniques that work well one year may be overwhelmed the next. Another issue is the nature of the crowd. According to Paul Townsend of Crowd Dynamics, a consultancy that has worked on the pilgrimage: "Pilgrims on the haj have the attitude that, if I die there it is God's will. There is a willingness to get more and more dense in the space." That isn't a factor that is easily included in the models.

[ED: On the dangers in certain places of bumping into somebody: the one time I visited New York City I bumped into a little businessman on the sidewalk, and his response was obvious fear. I was quick to reassure him I meant him no harm; the incident was half-amusing, but the other half was my own realization of just what kind of a place I was walking around in.] [TO BE CONTINUED]

START | PREV | NEXT | COMMENT ON ARTICLE* THE TORPEDO (3): War broke out between Prussia and the Austro-Hungarian Empire in June 1866, leading to a confrontation between the fleets of Italy, a Prussian ally, and Austria near the island of Lissa -- now the Croatian island of Vis -- in the Adriatic on 20 July 1866. The Austrians were outmatched, but thanks to superior leadership the Austrians inflicted a stinging defeat on the Italians, using ramming tactics. The Austrians did not do so well on the battlefield against Prussian forces, getting the worst of it in the "Seven Weeks' War" as it would be known, but as often happens in defeated nations, successes were played up, with the victory at Lissa being the focus of a rush of public enthusiasm. Whitehead was a beneficiary of the enthusiasm; ramming was of course dependent on steam power, and when the Austrian admiral who had led the navy to victory publicly praised Whitehead and his "first-class engines", the inventor became a celebrity of sorts and was given an award by the government.

It helped to establish Whitehead's credibility, and paved the way for tests by the Austrian Imperial Navy in December of a new weapon developed by Whitehead, what would be called the "auto-mobile [self-propelled] torpedo". The exact details of this prototype weapon remain unclear; Whitehead had been burned by patent infringements and so had become very secretive about his work. It is known that it was built of wrought iron and had a diameter of 35.6 centimeters / 14 inches, with a length of 3.5 meters (11 feet 7 inches). It was "dolphin-like" in shape, with fins top and bottom running its length to keep it from rolling.

It was powered by compressed air, with the pressure in the air vessel at 25 atmospheres. A sophisticated valve mechanism released the air at a constant flow rate up to depletion. The compressed air drove an engine of Whitehead's own design; although no engineering documents survive of the engine, it appears to have been a rotary device, with the compressed air driving a cylinder rotating along with a vane around the walls of a larger cylinder, driving a single two-blade propeller spinning at 100 RPM, protected by a guard ring. Depth was supposed to controlled by a hydrostatic valve driving elevator controls, while azimuth -- left and right direction -- was controlled by tabs on the rudder. It carried an 8.2 kilogram (18 pound) dynamite warhead, activated by a contact detonator on the nose of the torpedo. Range was about 180 meters (200 yards) at 11 KPH (7 MPH / 6 KT). Range could be extended with a lower speed setting.

Imperial Navy observers were impressed with the trials, but recognized that all they had at the time was a purely experimental prototype, in no way ready for service. Range, speed, and warload left something to be desired, but the real operational problem was that the torpedo was incapable of staying at a preset depth. Whitehead went back to the drawing board to refine the design and get it working right, while he kept the STF operation afloat.

* In 1868, in recognition of his services, the Austro-Hungarian Emperor awarded Whitehead the Order of Francis Joseph, which made him an Austrian baron. Further inquiries from the Imperial Navy on his auto-mobile torpedo followed, the admirals being interested to see if Whitehead had made progress on his weapon. He had, most significantly in developing an underwater launch tube. It was effectively an airlock with doors on both ends. The torpedo was loaded into the tube through the inner door, which was then shut, with the outer door opened to flood the tube. The torpedo was shot out of the tube by compressed air, riding on a guide rail that kept the weapon boresighted, the launch activating the weapon's compressed-air motor by yanking out a restraining pin. The outer door was then closed and the tube flushed out for reloading.

In addition, Whitehead had developed a "large" torpedo, with a diameter of 40.6 centimeters / 16 inches and a 30 kilogram (67 pound) guncotton warhead. He had improved the pressure vessel for his torpedoes to handle 82 atmospheres, fabricating it as a single piece of iron instead of boilerplate, boosting the speed to 20 KPH (13 MPH / 11 KT). Trials were supposed to begin in the spring, but one thing led to another and they didn't start until the fall. Results were dismal at the outset, with most of the test shots going astray, depth-keeping still being a very difficult problem. Whitehead asked for the trials to be suspended for three weeks while he puzzled things out.

As the saying goes, it concentrates a man's mind wonderfully when he knows he's to be hanged in the morning. According to the tale, and it fits well enough with the engineering mindset to be plausible, Whitehead discovered the key to solve his problems in the dark hours of the night, in a half-dreamstate, waking up to realize he had the answer. On fleshing out his idea, he came up with what would eventually be called a "balance chamber", which he initially placed behind the warhead.

The chamber featured a spring-loaded hydrostatic disk, open to water on one side while a rubber gasket kept the interior of the chamber dry, that could be adjusted to a setpoint; if water pressure changed to cause the disk to move in or out, a lever mechanism adjusted the torpedo's elevators to cause it to move back to its preset depth. A pendulum device was also hooked linked into the feedback control system, responding to changes in roll, pitch, or yaw to adjust the elevators or rudders and keep the torpedo on course. A few years later, Whitehead would more centrally locate the balance chamber between the air chamber and the engine, water pressure readings being affected more by the motion of the torpedo near the nose than farther back.

The same scheme would be standard kit on torpedoes up through World War II. It was a straightforward if not necessarily obvious notion, and Whitehead was very paranoid about others copying it -- melodramatically referring to it only as "The Secret" and telling no one about it without signing them to confidentiality. When the tests were resumed, the torpedoes proved deadly accurate. The only deficiency recorded by the examination board was that the torpedoes were slow, making them inadequate for ship-to-ship combat, but perfectly satisfactory for harbor defense. The Austrian Imperial Navy would have liked to have obtained exclusive rights to the weapon, but funds were lacking; they signed a nonexclusive contract with Whitehead that permitted him to sell his weapon elsewhere. [TO BE CONTINUED]

START | PREV | NEXT | COMMENT ON ARTICLE* GIMMICKS & GADGETS: Hard on the heels of the article run here in May on use of baseline cellphones as more general computing platforms, Finnish cellphone giant Nokia has introduced a set of new cellphones, the Nokia 110 and 111, to service the market in developing countries for "basic phones as personal computers".

The Nokia 110/111 "feature phones" are stylish but simple, with a basic keyboard, a small color display, and a VGA-class camera with video capability on the back. They also have an FM radio receiver and a digital media player capability, with a micro-SD card slot to allow expansion of memory to up to 32 GB. The phones have a micro web browser, which works through a server system that "predigests" internet traffic -- it appears in much the same way as BiNu, discussed here a few months back. The phones also have email and instant messaging capability, as well as access to 40 free games -- including Bejeweled, Tetris, Monopoly Here & Now, & SimCity Deluxe.

The Nokia 110 has dual SIM card capability; the 111 has single SIM card capability and a smaller battery. Nokia is also introducing the slightly flashier 112 and 113, functionally similar to the 110 and 111 respectively. Not bad for around $50 USD or less. It is interesting to wonder if these phones have any user programmability; it would seem that a simple scripting capability could prove very handy. Indeed, I can imagine a handheld computer along such lines, just with wi-fi instead of phone capability, and a small camera array for gesture input. It would be a great toy to play with.

* As reported by WIRED.com, the US Defense Advanced Research Projects Agency (DARPA), the Pentagon's blue-sky research office, is now working on the automation of clothing production. That may seem odd as a subject of military research, but armed forces spend a lot of money on uniforms, the US military being estimated to have spent about $4 billion USD on clothing in 2010. They also have unique requirements, such as different camouflage patterns for different environments, and (increasingly) integration with combat hardware.

DARPA has now awarded a contract to a research firm named Softwear Automation INC (SAI) organizations to develop "complete production facilities that produce garments with zero direct labor." SAI researchers say that the automation of clothing production isn't a new idea, clothing manufacturers have wanted it for a long time, but the smarts needed to pull it off weren't available. SAI thinks they are now. In the system envisioned by the company, an "overhead pick-and-place robot" grabs the required pieces of fabric and places them at the head of a sewing machine. The sewing machine would be equipped with vision capabilities, specific enough to spot and track individual fabric threads, providing "fabric location information" to actuators that operate the sewing machine's needle and thread, and "budgers" -- motorized balls underneath the sewing machine that latch onto the fabric via vacuum seal -- that move the material back and forth.

The advantages are obvious: cheaper clothes, production facilities moved back to the USA, and no bad press over exploitative sweatshops. The downside is that those exploitative sweatshops won't be hiring any more, putting people out of work. How that would be handled the article didn't say, nor could it have -- that problem having been posed as far back as the invention of the automated loom, leading to the legend of the semi-mythological Ned Ludd, who chose to smash his looms in outrage.

* As reported by THE ECONOMIST, one of the difficulties in operating robot aircraft off a carrier deck is that the deck crew guide an aircraft around the deck using hand signals. While a drone generally has a remote operator, trying to interpret the hand signals through a video link is troublesome. Researchers at the Massachusetts Institute of Technology (MIT) have been developing a gesture-recognition system to allow a drone itself to interpret the hand signals of the deck crew. Right now it's only about 75% accurate, nowhere near good enough to be safe to use on a carrier deck -- a notably dangerous environment, providing many opportunities for the incautious to get themselves gruesomely killed -- but the MIT researchers believe that it can be brought up to the same, or preferably better, level of accuracy as for a human pilot.

Once long ago I knew a guy who had been an "airdale", deck crew on a carrier, and he told me of one of the gestures -- involving holding one hand up and flat, palm down, then pressing the other hand as a fist up into the palm and abruptly jerking it down. It was to tell an inattentive pilot to be more alert, in typically military style: Pull your head out of your ass. I doubt that drones will be programmed to recognize that particular signal; a machine wouldn't understand the nuances involved.

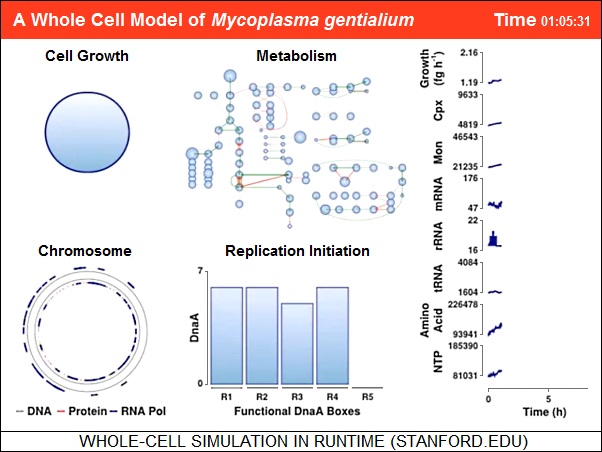

COMMENT ON ARTICLE* SOFTWARE BUG: As reported by article from THE NEW YORK TIMES ("In First, Software Emulates Lifespan of Entire Organism" by John Markhoff, 20 July 2012), researchers from Stanford University and the J. Craig Venter Institute have developed the first software simulation of an entire organism, a bacterium named Mycoplasma genitalium, which can infect in the human genital and respiratory tracts.

Various individual cellular processes such as metabolism have been simulated in the past, and they are now in widespread use. However, as the project leader, bioengineer Markus W. Covert of Stanford, pointed out: "Where I think our work is different is that we explicitly include all of the genes and every known gene function. There's no one else out there who has been able to include more than a handful of functions or more than, say, one-third of the genes."

Outside observers agree that the effort is something new, one saying that it was "the first truly integrated effort to simulate the workings of a free-living microbe" and commended it for its "audacity". The simulation, which runs on a cluster of 128 computers, models the full life cycle of the bacterium at the molecular level, tracing the interactions of 28 categories of molecules -- including DNA, RNA, proteins and small molecules known as metabolites, which are generated by cell processes. The simulation was constructed modularly, with various cellular sub-processes simulated by 28 modules, and the full cellular system simulated by hierarchically linking them together.

The simulation built on past experience with simulation of bioprocesses, the field being known as "computational biology". The simulation of the full life-cycle of the bacterium was still a big leap forward, and even with 128 computers is laborious: it takes ten hours to simulate the life of the bacterium from cell division to cell division, which ironically is about the same time it takes in the real universe. Incidentally, short of being consumed or dying of an accident, bacteria are immortal, replicating by repeated cell divisions.

M. genitalium, a pathogen associated with sexually transmitted disease, was selected because it has only 525 genes, the smallest number for any organism that can survive on its own. As a comparison, the well-known human colon bacterium Escherichia coli has 4,288 genes, about eight times as many. On the face of it, one might think eight times the genes would mean eight times the processing power, but it's not that simple, Covert pointing out that the larger number of genes means a multiplication of interactions. It's simple math that as the number of elements in a system rises by a factor of N, the number of possible interactions rises by (1/2) * N * (N-1), so a multiplication by eight would mean a maximum increase of 28. Increase N by further factors and it gets that much worse.

However, the researchers are eagerly looking forward to modeling more elaborate organisms. The point of the exercise was not so much to see if a complete organism could be modeled in software as it was to figure out how to trace the function of genes. We are familiar with genes that have particular functions, sometimes with a defective gene leading to a hereditary disease, but it's not typically that simple, with a particular function in an organism often directed by multiple genes, and a single gene having multiple functions. We make a fuss about the deciphering the genomes of organisms, but that's easy compared to figuring out what the genome does. It is one thing to print out books; reading books with hideously complicated plots is a bigger challenge.

COMMENT ON ARTICLE* INVENTING MATERIALS BY COMPUTER: As discussed in an article from SCIENCEMAG.org ("Materials Scientists Look To A Data-Intensive Future" by Robert F. Service, 23 March 2012), ever since the invention of quantum mechanics, chemists have had the ability in principle to calculate the properties of any sort of molecule or crystal without actually fabricating it. That suggests we could take the desired properties of a material, feed them into a computer, and get back the appropriate formula for that material.

However, the qualifier "in principle" is significant, because as the complexity of possible materials grows, the computational overhead goes through the roof and heads for the Moon. Even the relatively uncomplicated materials investigated to date have been analyzed using simplified and approximate techniques -- such as Monte Carlo simulations, where calculations are driven by samplings of random values instead of burdensome complete data sets. Now materials researchers are finding the impossible within reach, not due to any breakthrough in the software, but because of the widespread availability of supercomputer power. Says materials scientist Gerbrand Ceder of the Massachusetts Institute of Technology (MIT): "The scaling of computer power is really making this possible."

In June 2011, the US government initiated an awkwardly-named "Materials Genome Initiative (MGI)" program to promote the use of intensive computing to accelerate materials development, particularly for applications in alternative energy systems. The US National Science Foundation and Department of Energy have subsequently been passing out grants for computational materials research. Early targets for this effort include improved catalysts, battery materials, and thermoelectrics -- that is, materials that convert heat into electricity.

Once the work gets rolling, advocates believe progress will be rapid. Ceder says there are between 50,000 and 100,000 different known inorganic compounds. Crunching the numbers for all the computable properties of any one material -- such as crystal structure, stability, ionic mobility -- would take about a day on a desktop PC, while crunching through all of the known inorganic compounds would take up to about three million hours of computer time. If that sounds like a lot, a top-of-the-line supercomputer could deal with it handily in less than two days.

Even examining speculative candidate materials not on the list of known materials would "only" take about 500 million CPU hours, well within the reach of current supercomputers, Ceder calling that a "drop in the bucket" of available supercomputing horsepower. Ceder comments: "We don't know most things about most materials. Materials scientists are hungry for this data."

Those working in computational materials design don't believe that computers will be able to deliver advanced materials by themselves, the computers instead identifying sets of candidates for lab analysis. Ceder is taking such an approach in his own "Materials Project" at MIT, initiated in 2005 to uncover advanced materials for batteries. Since that time, the researchers working on the project have computationally evaluated over 80,000 materials and screened 25,000 of them in the lab. A recent paper from the project indicated via computational analysis that a new vanadium-based cathode material would increase the storage capacity of lithium-ion batteries by 10%; the material was then synthesized and worked as predicted.

Other research projects at MIT and elsewhere are working on improved thermoelectrics, new catalysts to allow sunlight to split water into oxygen and hydrogen, and in particular new materials for computer chips. Chips are reaching the smallest scales possible with existing materials; to go even smaller demand figuring out new materials. However, Ceder points out that while current computational materials research is well-suited to some applications, such as battery components, it is not to others, particularly lightweight materials -- since in that case the properties of the materials are determined by long-range effects through their structures that current simulation schemes can't handle.

Krisha Rajan, a materials researcher at Iowa State University, is working on software to deal with such computationally intractable materials, his software focusing on machine learning instead of working from first principles of physics. The Iowa researchers decided to focus on piezoelectric materials -- materials that generate electricity when squeezed, or change configuration when electricity is run through them -- as a start, creating a database of known characteristics and properties of piezoelectrics, then used an evolutionary analysis or "genetic algorithm" to establish relationships between the characteristics and the properties. Using this software, the team was able to zero in on new piezoelectrics with good performance at high temperatures.

The Iowa researchers have been able to use the same approach for other materials problems, but Rajan says they still have a long ways to go, that adding new factors to get better results ends up being "too complex". However, despite the limitations of the approach, he feels it likely it will have a "huge impact".

COMMENT ON ARTICLE* GO WITH THE CROWD (1): As discussed in an article from THE ECONOMIST ("The Wisdom Of Crowds", 17 December 2011), it is obvious that crowds of people are surprisingly orderly in an informal way. Aside from the infrequent panics that make crowds dangerous, everyone seems to be able to get where they want to go without too much trouble.

They do so by following a simple set of rules. In Paris, for example, if two pedestrians are on a collision course, they usually step to the right. In many parts of Asia they step to the left. Oddly, there is no real correlation between this rule and what side of the street people drive on; in London, pedestrians shift to the right. It's just whatever the local custom is.

Researchers are now trying to model the behavior of pedestrians. It's not just an exercise in academic wool-gathering; crowd management is an important issue, and under difficult circumstances, as discussed here in 2005, it can be of life-or-death importance. In 1995, Dirk Helbing and Peter Molnar, physicists at ETH Zurich in Switzerland, developed a "social force" computer model that used insights from the way that particles in fluids and gases behave to describe pedestrian movement. The model assumed that people have goals in their movements, primarily their destination, while being confronted with obstacles to their movement. The model proved its worth by predicting several "self-organizing" effects among crowds that can be observed in the real world.

One is the inclination of dense crowds to spontaneously form into lanes that allow people to move more efficiently in opposing directions, with people in each lane following each other instead of having to deal with oncoming foot traffic. Mehdi Moussaid of the Max Planck Institute in Berlin did further studies that showed when people in a lane got impatient and tried to get ahead of those in front of them, it tended to disrupt the opposing lane and slow everyone down as a result. Go with the flow.

Another self-organizing behavior occurs when opposing flows of people meet at an intersection. As people cross in one direction, the pressure on their side of the intersection drops. That gives those waiting on the other side more opportunity to get through, and they cross until the pressure on their side is relieved. The result is a series of alternating bursts of back-and-forth traffic. Helbring believes this behavior should be applicable to traffic control, with lights at intersections adapting locally to buildup of traffic in either direction, adapting to circumstances to gate vehicles through in the most efficient fashion.

However, going beyond simple models of pedestrian behavior is difficult, one big reason being cultural differences -- as noted above, people keep to the right or left in different locales as per custom. That's not so hard to factor into models, but there are other differences between locales as well; for example, in India pedestrians tend to walk faster than they do elsewhere, it seems because they don't get particularly upset when then bump into each other. In really paranoid places, bumping into someone can lead to homicide.

Another factor is that pedestrians are not necessarily operating on their own -- the majority are walking in groups, such as families and associations of friends. Groups tend to respond together and bunch together to maintain their integrity. Observations of pavement crowds in Toulouse in France show that clusters of three and four people naturally organize themselves into concave "V" and "U" shapes, with middle members falling back slightly. If a group of three people wanted to move quickly, they would act like geese and form an inverted "V", with the middle member slightly in front to forge a path. In reality, they adopt a formation that allows them to communicate with each other. [TO BE CONTINUED]

NEXT | COMMENT ON ARTICLE* THE TORPEDO (2): The "better idea" that would render naval weapons such as the spar torpedo obsolete was the brainchild of Robert Whitehead, an engineer born in 1823 to a prosperous industrial family of Bolton in Lancashire, England. In the last half of the 1840s, lured by good-paying jobs, Whitehead left England to work in France and then Italy, being employed in Milan as a consultant on industrial technology. He was doing well for himself until 1848, when a wave of revolutionary uprisings swept across Europe. Whitehead found his work completely disrupted and was appalled by the fighting in the streets of Milan; he relocated himself and his family to Trieste on the Adriatic, where he obtained a job with Stabilimento Strudthoff, an Austrian maritime engineering firm.

The job paid well and Whitehead was good at his work, developing technologies for improved maritime steam engines -- most significantly a cylindrical boiler. Somewhat surprisingly, up to that time boilers had been boxlike in configuration, though that meant they couldn't deal with high pressures as well. Whitehead gradually chafed at being an employee, however, and when in 1856 a group of financiers operating under the name of "Stabilimento Tecnico Fiumano (STF)" offered him the opportunity to manage their new engineering works at Fiume, not far down the coast from Trieste, he jumped at the chance.

The financial backers of STF were content to allow Whitehead to run the factory as he saw fit while they took care of the finances, and the operation flourished, in particular establishing a close relationship with the Austrian Imperial Navy Office in Vienna. The wave of uprisings of 1848 had run its course, but it had left considerable instability in its wake, one consequence being that Austria began a naval buildup in the Adriatic. STF prospered, with Whitehead's sound designs for maritime steam engines proving highly satisfactory in use on Austrian warships, and the firm even building ironclad warships for the Austrian Imperial Navy.

Whitehead's engineering work tended towards the conservative, but it also led him towards an innovation, though the idea wasn't essentially his. In the early 1860s a retired Austrian naval officer, Commander Giovanni de Luppis, constructed a model of an unmanned boat, powered by clockwork, carrying an explosive charge set off by a contact detonator on the prow of the little vessel. It would be directed towards its target by lines manipulated by an operator on the shore.

De Luppis showed off the model of "Der Kuestenbrander (Coastal Fireship)" to naval authorities in Vienna -- and they gave it a thumb's down, finding the propulsion and control schemes impractical. Much to their credit, however, they believed de Luppis had the seed of a good idea, and encouraged him to find a professional to help him flesh it out. De Luppis knew Whitehead by reputation and met with him sometime in 1864. Whitehead's reaction was much the same as that of the authorities in Vienna -- the idea didn't sound practical in itself, but there seemed to be something in it. The two men labored together to build a prototype. Despite months of effort, however, they couldn't get things to work and the two men, it appears more in sorrow than in bitterness, went their separate ways.

However, as might be expected for the engineering mind, Whitehead could not let go of the idea, and found himself thinking it over and over, to the detriment of his other work. What he finally realized was that a surface boat wasn't the way to go; it was too easily detected, too easily frustrated once detected. But what if the weapon made its way to the target underwater? Not only would the weapon remain unseen, it would hit the target below the waterline, hopefully sinking it. The more Whitehead thought about the concept, the more he was convinced it was the way to go. However, it posed a tangle of practical issues in propulsion, control, and maintaining a preset depth underwater. He decided to focus all his energies on the task, working in a small hut in a corner of the STF factory grounds, attended by his 12-year-old son John and a mechanic. [TO BE CONTINUED]

START | PREV | NEXT | COMMENT ON ARTICLE* Space launches for June included:

-- 01 JUN 12 / INTELSAT 19 -- A Sea Launch Zenit 3SL booster was launched from Sea Launch Odyssey platform in the equatorial Pacific to put the "Intelsat 19" geostationary comsat into orbit. The spacecraft was built by Space Systems / Loral and was based on the SS/L 1300E comsat platform. It had a launch mass of 5,600 kilograms (12,350 pounds), a payload of 34 Ku-band / 24 C-band transponders, and a design life of 15 years. It was placed in the geostationary slot at 166 degrees east longitude to provide communications services to the Pacific Rim. There was some anxiety when one of the satellite's solar arrays failed to deploy, but it finally popped loose on 12 June. The array was damaged, however, and operational power capacity was permanently reduced.

-- 13 JUN 12 / NUSTAR -- An Orbital Sciences Pegasus XL booster was launched from the Orbital Stargazer carrier aircraft operating out of Kwajalein Atoll to put the NASA "Nuclear Spectroscopic Telescope Array (NuSTAR)" X-ray astronomy satellite into orbit. NUSTAR was discussed here in detail a year ago.

-- 16 JUN 12 / SHENZHOU 9 -- A Long March 2F booster was launched from Jiuquan to put the "Shenzhou 9" crewed space capsule into orbit, delivering three Chinese taikonauts to the Tiangong 1 space station, launched on 29 September 2011. This was the fourth Chinese crewed space mission. The crew included commander Jing Haipeng (second spaceflight), pilot Liu Wang (first spaceflight), and medical officer Liu Yang (first spaceflight), Liu Yang being the first female taikonaut. Shenzhou 9 docked with Tiangong 1 two days after launch, with the crew landing safely in Inner Mongolia on 29 June after 13 days in space.

-- 20 JUN 12 / NROL 38 -- An Atlas 5 booster was launched from Vandenberg to put a secret military payload into space for the US National Reconnaissance Office (NRO). The payload was designated "NROL 38" and was apparently a Satellite Data System geostationary intelligence data relay spacecraft. This was the 50th launch of an "Evolved Expendable Launch Vehicle (EELV)". The booster was in "401" configuration, with a 4 meter (13.1 foot) diameter payload fairing, no solid rocket boosters and a single RL10 engine in the Centaur upper stage.

-- 29 JUN 12 / NROL 15 -- A Delta 4 Heavy booster was launched from Cape Canaveral to put a secret military payload into space for the US National Reconnaissance Office (NRO). The spacecraft was designated "NROL 15", and may have been a geostationary signals intelligence satellite.

COMMENT ON ARTICLE* SOLAR INDIA: As India struggles to develop its economy, one of the major critical paths is obtaining more electrical power. Although India's primary power source is coal, there is also interest in renewables, Indian efforts to develop wind power having been discussed here in 2007. As discussed in an article from THE NEW YORK TIMES ("In Solar Power, India Begins Living Up To Its Own Ambitions" by Vikas Bajaj, 28 December 2011), India is interested in solar power as well.

Welcome to Khadoda in northwest India. It's a dry region, hot and sunny nearly all year round, and generally an ideal site for extracting power from the sun. It is, however, also dusty, and so every five days or so field hands use long-handled dustmops to wipe down all 36,000 solar panels at a facility run by Azure Power, under contract to an electric utility run by the state government. Inderpreet Wadhwa, Azure's boss, is bullish on solar, claiming it will soon be competitive with coal: "The efficiency of solar technology will continue to increase, and with the increasing demand in solar energy, cost will continue to decrease."

In 2009, Indian policy makers said that they wanted to ramp up Indian use of solar power to 20 gigawatts (GW) by 2020. India's solar power capacity is growing rapidly, thanks to government subsidies and a big drop in the global price of solar panels. Right now, Indian solar power capacity is 140 megawatts (MW) total, impressive given that it's sprung up from almost nothing, but still a drop in the bucket compared to the 20 GW target. In comparison, Germany has about 17 GW of solar capacity.

Indian solar power advocates are optimistic that the growth rate is going to increase; after all, if Germany, with only about a tenth of the land area of India and cloudy as well, can get 17 GW of solar power, sunny India should be able to do better. Chinese manufacturers like Suntech Power and Yingli Green Energy helped push the drop in solar panel costs, increasing production and dropping the pricetag to up to 40%, to less than $1 USD a watt. Indian solar power developers, however, have preferred the "thin-film solar" cells offered by suppliers in the United States, Taiwan and Europe. India is also trying to develop its own solar panel production capability.

While Indian businesses tend to distrust the government, notorious for its inefficiency and bureaucracy, solar power developers have been getting along fairly well with the system. The government controls power utilities, but has been willing to farm out renewable energy development to private concerns, handing out subsidies to encourage competition. Solar is still about twice as expensive as coal, but given that Indian electrical power generation capacity badly lags needs, any additional power is welcome -- and everyone expects solar costs to come down.

Indian companies investing in solar power plants see both opportunity and risk, the risk being that India's solar boom is likely to lead to a shakeout. Says Azure Power's Wadha: "Initially, a lot of new players enter the sector, and then the market settles with a few players who have a long-term [commitment to the industry]". Wadha can only have faith that Azure Power will be one of the survivors.

* SCRATCH IT OFF: Solar power has a lot of potential for the developing world, since many developing countries are sunny, and poor people don't really need a lot of electricity -- a cheap solar panel can provide all the juice they require. The problem is that, being poor, they don't have the money to buy even a cheap solar panel.

As reported by THE ECONOMIST ("Starting From Scratch", 3 March 2012), a UK company named "Eight19" -- a spinoff of Cambridge University -- has come up with a clever business model to make solar power more affordable to the poor. In return for a deposit of about $10 USD, Eight19 is providing poor families in Kenya with a solar power system that includes a panel able to produce 2.5 watts of electricity, a battery to store the electricity, and an energy-efficient LED lamp. The firm estimates that a fully-charged battery will be able to provide lighting and charging for a mobile phone for seven hours. When the sun comes up, the battery can be recharged.

To actually use the power system, the user must buy a scratch-off card at a base cost of about a dollar, on which a code number is printed. The user sends the code number to Eight19's server with a mobile phone text message, with the server shooting back an access code for the power system control unit, which then doles out another installment of electricity until the value of the scratch-off card is used up. After buying around $80 USD's worth of scratch cards -- which Eight19 figures should take an ordinary family about a year and half -- the user owns the panel. It can then be used entirely for free, or traded in for a more powerful unit, with scratch cards used to pay that off as well.

Eight19's accountings show the scheme is a no-brainer for the poor, since even while they're paying off the panel, they're still only spending about half as much as they would for lighting -- by kerosene lamp -- and cellphone power. The economics will get even better as the cost of solar power continues to fall. Following the pilot program in Kenya, Eight19 is working towards similar efforts in other African countries.

ED: One wonders if the system has theft protection features. Given that the solar panels are controlled via the phone network and obviously have serial numbers to make them individually recognizable, it would seem straightforward, at least on the face of it, for an owner who loses a solar panel to thieves to phone in a request to shut the panel down. That wouldn't get their panel back, but at least it would give thieves less incentive to lift them, and grant the owner the satisfaction of spiting the thieves.

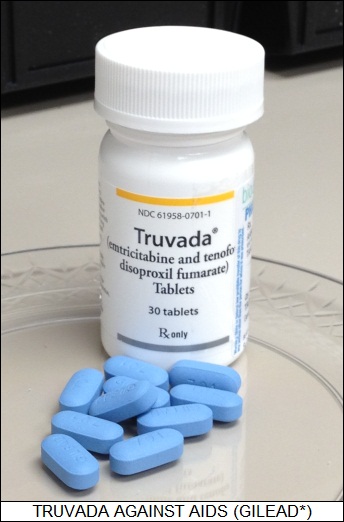

COMMENT ON ARTICLE* THE AIDS BUSINESS: The global AIDS pandemic has led to a huge mobilization of resources to fight it, and as discussed in an article from THE ECONOMIST ("The Business Of HIV", 2 June 2012) it necessarily has a major commercial aspect. In 2011 sales of anti-retroviral (ARV) drugs, used to control the HIV retrovirus, in the USA and the five biggest European markets were $13.3 billion USD. It is, however, a funny sort of business, necessarily boosted by government support and inevitably uncomfortably dependent on it. Along with government financing, publicly funded research has played a larger role in developing drugs for HIV than for other diseases; a recent study found that HIV drugs were three times as likely to involve a patent from the public sector. HIV also has special status among regulators. America's Food and Drug Administration (FDA) has set up a "fast track" review system for HIV drugs, allowing them on the market before the most expensive stage of clinical trials.

Public and private investment has now produced more than two dozen HIV drugs. In 1987 Burroughs-Wellcome, now part of GlaxoSmithKline, introduced the first, targeting an enzyme that helps the virus replicate inside human cells. In 1995 Hoffmann-La Roche, a Swiss drug firm, launched the first "protease inhibitor", which interrupts the virus at a later stage of replication. HIV is a tricky pathogen, able to mutate around drugs far more rapidly than other pathogens, and the development of a range of ARVs has led to "cocktails" in which several of these drugs are combined -- meaning HIV would have to mutate around all of them simultaneously to survive. The emergence of combination therapy has led to a flurry of cross-licensing as companies trade in each other's drugs.

The current leader in ARVs is Gilead of California, even though the firm was late to the market. Gilead has a straightforward strategy, focusing on convenience of treatment. In 2004 Gilead launched Truvada, a once-a-day, one-pill combination of two drugs. In 2006 it introduced Atripla, a once-a-day, one-pill combination of Truvada and another treatment. It doesn't come cheap; Atripla's average wholesale price in the USA is nearly $25,000 USD per patient a year. In 2011, global sales were a staggering $3.2 billion USD. Gilead isn't stopping there, either. An FDA panel has recommended Truvada for preventive use -- that is, to protect healthy people from contracting the virus. Another FDA panel endorsed Gilead's new Quad pill, which is the simplest, most effective combination drug to date, hitting HIV with four drugs that reduce the probability of emergence of drug resistance to the infinitesimal.

Given the expense of ARVs, the sales models are unorthodox as well. America is the rich world's biggest market, with 841,000 patients diagnosed -- ten times as many as in the UK. More than 60% of HIV drugs in America are bought with public money. Insurers give HIV special treatment, with patients rarely pushed to buy the cheapest drugs, as they might be for a more orthodox ailment.

What about the poor world? A decade ago, hardly any poor folk could afford ARVs, and early on the drug firms lived up to their reputation for callous greed -- in 1998, 39 big Western firms sued South Africa to protect HIV patents. It was a public relations disaster, and the drug firms gave up the fight in 2001. The drug firms had to make a profit to pay off the expense of developing drugs and to stay in business, but they couldn't be seen as indifferently letting poor people die, either. Matters had to be rethought.

Two things happened to change the landscape. The first was public support, as rich countries started donating huge sums to help fight AIDS in poor ones. In 2000 there was less than $2 billion USD for HIV programs each year; by 2010 there was $15 billion USD, thanks to the Global Fund to Fight AIDS, Tuberculosis and Malaria and the George W. Bush President's Emergency Plan for AIDS Relief (PEPFAR) -- one of the most positive and unappreciated accomplishments of Bush's controversial administration.

The second was the fall of ARV prices due to manufacturing maturity, and a more thoughtful approach on the part of companies to intellectual property rights. In 2000 a year's "triple cocktail" therapy cost $10,000 USD or so, but by 2011 the same pills sold for $62 USD in poor countries. PEPFAR cash buys drugs developed by big drug firms and protected by patent, but made by low-cost generic manufacturers, produced and sold on the condition that they are only supplied to poor countries. It was a deal that made everyone happy, the big drug firms concentrating on rich countries where they could make a profit, leaving the poor countries that weren't worth their time to the generics producers, obtaining some compensation via modest royalties. Last year two drugmakers won most of PEPFAR's contracts: Aurobindo, an Indian firm, and Matrix, an Indian firm acquired in 2007 by Mylan, an American company. PEPFAR's bidding system keeps margins slim even by the standards of the generics industry, says Rajiv Malik, the president of Mylan, but volumes are huge.

What about the future of the market? Only about half those infected by HIV take ARVs, blocked from doing so by circumstances or ignorance, and reaching that unprotected half has proven difficult. However, the half that does have access to ARVs has to take them for the rest of their lives, and that means a guaranteed market for the product. The use of HIV drugs as a preventative measure also means an expanding market.

On the other hand, support for ARV programs from rich countries has declined due to the global financial crisis. Another challenge faced by the drug companies is that ARVs have matured, and there's no longer as much of a push by patients and their advisers to obtain the latest, best, and most expensive product when older and cheaper concoctions can do the job. Worse, by 2017 many ARVs will be losing patent protection and then prices will crash. Ironically, although the ultimate goal of HIV research is to find a vaccine or cure, should we ever figure out how to really defeat HIV, the big drug firms will put themselves generally out of that business.

COMMENT ON ARTICLE* RETHINK THE SYSTEM (6): Once I moved the blog off of Vectors I figured I was pretty much done, but then I got feedback that navigating between the different websites was not intuitive. I got to thinking that over and started cooking up a "big banner" for the root page on each of the websites that provided navigation for the website as well as banners to the other. After fiddling with it, I found it made the sites look much tidier.

Then I had a brainstorm: I'd been thinking of moving the DayVectors blog to its own website, but on consideration of its light traffic load that didn't make any sense. Still, I wasn't happy with it as part of the AirVectors website, mostly because I saw it as complicating ad targeting. I figure the AirVectors site is likely to be the most attractive for specialized advertising; no use in doing anything to discourage advertisers. Very well, why not just get a domain name for DayVectors from Fatcow and set up a second website in the same hosting account?

I did so and set up forwarding links from AirVectors to the new website. Now I have three distinct websites -- or maybe "more or less distinct" would be more apt, since Fatcow won't give me separate stats on the two websites they host. I think AWSTATS can do it, but Fatcow didn't feel like messing with it. No worries, I can live with that.

It turned out that as Fatcow had it, the stats for both websites were consolidated; that is, I'd get a single count for visits to the "index.html" files on both. However, for the most part I had different file prefixes for the pages on the two sites, meaning I could sort out visits on a file-by-file basis. The only particularly tricky item was the "index.html" file since I had to have one on both sites -- but I ended up rooting the blog site on "gblog.html", the current blog file, setting up "index.html" on the blog site as a redirection file, and then putting a freebie hits counter on it so I could sort it out from the "index.html" file on AirVectors. There were a few other common files, such as "donate" pages, but sorting them out was no big worry.

Having set up forwarding links on AirVectors really confused my stats for June since I had duplicate file names for all the blog pages, so I dropped all the forwarding links at the end of the month. That wasn't really user-friendly, but I figured that was long enough to tip off search engines and regular readers that things had changed.

So all seems stable now, except for uploading my photos to Flickr, an ongoing sink for time, looking to be done by mid-August. The other frustration is that I'm going to be operating at a loss for the foreseeable future. I'll have to see how that goes, and what I can think up to bring in money. I can be patient; I'm paid up on my web services until the spring of 2013, I'll see how things are working by the end of the year. [END OF SERIES]

START | PREV | COMMENT ON ARTICLE* THE TORPEDO (1): Up to the middle of the 19th century, naval warfare had been generally static for several centuries; a sailor of 1650 would have not found all that much unfamiliar with a typical warship of 1850. To be sure, steam power had been developed, but it was mostly used for ferries and riverboats at the time, and ships traveling the oceans still generally relied on sail -- one of the big reasons being that using steam power to travel the high seas was predicated on the availability of an international network of fueling stations.

By 1850, however, steam was reaching the tipping point, being the leading edge of a revolution in naval warfare. By the year 1900, warship technology had been changed all out of recognition, not just by steam power but by armor, much more powerful and capable naval artillery -- and the torpedo. This series provides a history of the torpedo, based mostly on Edwyn Gray's 1991 book THE DEVIL'S DEVICE.

* The "torpedo" is a fish, a member of the family of skates and rays, that has the ability to defend itself with a powerful electric shock. During the American Revolution, an American inventor named David Bushnell had developed a little man-powered submarine, the TURTLE, which he armed with a gunpowder mine; he intended to sneak up on a British warship with the TURTLE, attach the mine, and sneak away again before a timer blew up the charge. Bushnell called the mine a "torpedo".

It wasn't really a new idea, people had been tinkering with naval mines in various forms for over a century, but Bushnell was one of the first to use the scheme in combat. Attempted attacks by the TURTLE in 1776 against blockaders in New York harbor failed, however, and Bushnell was reduced to floating power kegs fitted with timers against British blockaders. They didn't prove very effective, either.

In 1797 another American inventor, Robert Fulton, picked up where Bushnell left off, inventing a more sophisticated man-powered submarine that he named the NAUTILUS. It was armed with a "towed torpedo" -- a charge hauled on a line behind the submarine. The idea was that the submarine would cross underneath its target, to rise slightly and drag the line across the bottom of the vessel, the torpedo going off on contact. He demonstrated the NAUTILUS to French authorities in 1800. The submarine didn't work out well, so Fulton focused on various schemes for towed and static torpedoes; since the French hadn't been impressed by his work, he tried to interest the British in his schemes as well. The British Admiralty awarded him a generous contract but then had second thoughts, seeing Fulton's torpedoes as more of a threat than a benefit to British naval power, and terminated their relationship with him.

Fulton was able to keep the money he had been granted, apparently on the condition that he didn't try to sell his ideas to the French, so he returned to the United States, where he worked on steamboats -- and, as a sideline, on weapons. During the War of 1812, he did further work on submarines and in particular on torpedoes, the Americans setting up something of a cottage industry in devising explosive devices to blow Royal Navy ships out of the water. The torpedoes didn't end up doing much damage, but the British found them "damned unsporting" and were inclined to anger when torpedoes were used against them, occasionally raiding harbors from which they had been launched.

Fulton died abruptly in 1815, a premature end to an inventive mind, but work on torpedoes continued. Samuel Colt, the famed inventor of the first practical revolver, tinkered with electrically detonated static torpedoes from 1829, destroying target vessels in demonstrations. It wasn't until the American Civil War that torpedoes were put to practical use; the Confederates were very fond of static torpedoes, and though their devices were notably unreliable, they did score a number of significant "kills" on Union vessels. Union sailors also found torpedoes "damned unsporting" and tended to react angrily when they were used against them.

The Union did not have much need for static torpedoes, the Confederates not posing any real offensive threat to Northern harbors and rivers, but both sides did use "spar torpedoes" -- a notion tracing back to Fulton at least, in which a charge was mounted on a long pole in front of a vessel, such as a steam launch, or one of the Confederate efforts at submarines or submersibles. Both sides scored kills with their spar torpedoes. The concept left a lot to be desired, of course, since it meant that the torpedo boat had to come up against an unsuspecting target and then blow up a heavy charge right in front of itself. The spar torpedo did persist in service with various navies for several more decades, but it would be bypassed by a much better idea. [TO BE CONTINUED]

NEXT | COMMENT ON ARTICLE* SCIENCE NOTES: It is well known that there are locales in the ocean where plastic trash tends to accumulate. As discussed in an article from SCIENCEMAG.org ("Ocean Trash Is A Lifesaver for Insect" by Daniel Strain, 8 May 2012), while it isn't generally thought the trash does most of the sea life much good, it turns out to be extremely useful for an ocean-living insect named Halobates sericeus.

The bug is thriving in the "Great Pacific Garbage Patch", a region between California and Hawaii where floating debris tends to accumulate. That generally brings up a vision of a patch of seas covered with trash, but Miriam Goldstein, a marine ecologist at the University of California in San Diego (UCSD), says that's misleading. Most plastic that accumulates there tends to be small, usually tiny particles of polystyrene and other buoyant plastics no bigger than a popcorn kernel, making it effectively invisible from the deck of a boat. The density of debris has, however, been rising steadily over the past few decades, though it's still only about one piece of debris per ten cubic meters of surface water.

While investigating debris obtained from the patch, Goldstein and her colleagues got a surprise, finding that the particles often were decorated with one or two bright orange eggs. Puzzled, they checked up on the matter and found they were eggs of H. sericeus, an oceanic relative of the water strider. Checking out past samples of debris indicates that the H. sericeus eggs are becoming more common.

Unlike all but a handful of bugs, H. sericeus spends its entire life at sea, but it still needs to lay its eggs on something solid. In the past, the bugs have used chunks of buoyant volcanic pumice or even bits of wood, both of which are rare on the open ocean. Now, with more floating nurseries to choose from, Goldstein says the bugs could be in for a population explosion. Exactly what that would do, nobody knows; the bugs could deplete marine plankton, or lead to a boom in the population of marine crabs that feed on them. Goldstein says: "This is an ecosystem that doesn't have many nutrients. There's a lot of things there that are hungry all the time."

* As reported by SCIENCEMAG.org, examination of the tree rings of two old Japanese cedar trees have shown that in the growth year 774:775 CE, the ratio of the carbon-14 isotope to the normal carbon-12 isotope jumped by 1.2%. This anomaly had been observed in other studies, but had only been narrowed down to a decade; now it's been pinpointed to a specific year.

The carbon-14 increase has been judged to be due to a heightened influx of cosmic rays striking the Earth's upper atmosphere, converting atmospheric nitrogen-14 into carbon-14. The puzzle is where the cosmic rays came from: even the most powerful solar flares couldn't do the job, and there are no known supernova remnants corresponding to an event that year. Writings from that time make no particular mention of unusual celestial phenomena, and so exactly what caused the 775 CE anomaly may be hard to figure out.

* It's well known that miniature variants of large animals are often found on islands, where the available land area doesn't support very big animals well, and there are few predators to make size a great advantage. As reported by BBC.com, paleontologists have now discovered a "mini mammoth", a mammoth that only grew to a meter in height at the shoulder, that lived millions of years ago on the island of Crete.

It's not exactly a new find, the fossils were discovered over a century ago, but nobody was quite sure what to make of them. The teeth analyzed in the study were originally collected by fossil hunter Dorothea Bate in 1904. They were first thought to be of a dwarf elephant, but now an analysis suggests they were of a mammoth. The fossils appear to be about three million years old. Being a fan of Phil and Kaja Folio's goofy and ingenious steampunk web comic GIRL GENIUS, this item caught my eye, since the berserk fantasy world in which the action takes place includes as a background element "mimmoths", which are rat-sized mammoths. They are apparently a popular treat, food concessions often selling the tasty "mimmoth on a stick".

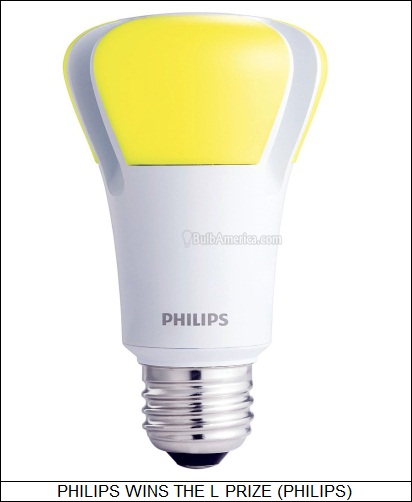

COMMENT ON ARTICLE* LED LIGHTING GETTING NEARER: The prospects for illuminating our households with light-emitting diodes (LEDs) was discussed here in 2011, showing how LEDs offer much higher efficiency and durability than other forms of lighting, and are more environmentally benign than compact fluorescent lights (CFLs), which contain mercury. The only problem with LED lighting right now is cost; it's just too expensive for ordinary usage. As discussed in an article from IEEE SPECTRUM ("LED Bulbs For Less" by Richard Stevenson, January 2012), that's not going to be the case for too much longer.

Right now, a 40-watt equivalent LED bulb can be had for $10 USD, still above the breakeven point with CFLs in most applications, but brighter LED bulbs are becoming available as prices keep dropping. As a hint of what's coming, this last August a LED lightbulb from Philips Lighting North America that is represents the direction of the technology won the US Department of Energy's (DOE) $10 million USD "Bright Tomorrow Lighting Prize:, better known as the "L Prize". Philips officials call their L Prize bulb the "Ferrari of lighting" -- which is a little ironic because at the outset it sold for a Ferrari price, about $50 USD, but the price is certain to fall.

The L Prize had stiff specifications: the bulb had to put out at least 900 lumens, as much as a classic 60 watt incandescent bulb, while it had to last 25,000 hours, about 25 times as long as an incandescent bulb, and draw less than 10 watts. Philips based the bulb on the Luxeon Rebel LED, which uses a mirrored back surface and roughened upper surface to provide a high level of light output.

The bulb also features omnidirectional emission, which is a little tricky to pull off because an individual LED generates its own beam. Traditionally, white LEDs are made by applying a yellow phosphor to a blue-emitting chip made of gallium nitride and indium gallium nitride. That way, the mixing of the yellow emitted by the phosphor and the blue that passes through it combine to create white light, but only from the coated face of the chip. Philips gets around this problem by putting the phosphor close to the outside of the bulb and illuminating it fairly evenly with a battery of 18 LEDs, with the phosphors diffusing the light into a warm uniform glow. Test subjects found it difficult to tell the light from the LED bulb from light from an incandescent bulb.

In addition, the L Prize required that a LED bulb had to tolerate mechanical shock, temperature extremes, high humidity extremes, and variations in supply voltage. DOE officials testing the LED bulbs found that all the LED bulb candidates passed the environment tests, while good-quality CFLs all failed.

Price is likely to steadily drop with technological improvements, such as larger wafers for LED chips, and as volume grows. China is seen as the market driver, with the government there offering attractive incentives to firms to get them into the business. Right now China is behind the learning curve, with most Chinese firms just producing discrete LEDs for Christmas lights and the flashing heels of children's sneakers. The technology for manufacturing LED bulbs that could meet L Prize standards is much more challenging, and it will take time for Chinese manufacturers to figure it out.

Even today, however, China's aggressive push into less challenging LED applications, such as display backlighting, is helping drive LED bulb technology, since it pressures the competition in those markets, forcing them to seek a market advantage in LED bulbs. How much money vendors such as Philips can make with LED bulbs over the near term is unclear: even at current prices, LED bulbs are cheaper on a life-cycle basis than incandescents, but as mentioned LED bulbs can't compete on that basis with CFLs. That's going to change, however, and it is inevitable that the CFL will become an interim technology, a relatively short-lived stage in the transition from incandescents to LED bulbs. [ED: As of 2023, LED bulbs have taken over the world. Not only is my house full of them, but I have some that generate color patterns, and centrally control them via voice. Many of the things I wrote about never amounted to much, but LED bulbs did with a vengeance.]

COMMENT ON ARTICLE* PAINT AGAINST INSECTS: As reported by an article from BUSINESS WEEK ("Killing Bugs By Painting Your House" by Nick Lieber, 21 May 2012), a Spanish chemist named Pilar Mateo has set up a company named "Inesfly" to promote her bright idea: paint laced with microcapsules of insecticide. Once a house is painted with it, it releases insecticides at a low level for two to four years; the insecticides are targeted at insect biology, with tests showing they cause no visible harm to humans, while putting insects out of business. The insecticide leaks out of the paint at a relatively constant rate, helping reduce the inclination of pests to develop resistance in the face of spotty application of pesticides.

Mateo developed her invention in a roundabout way. She acquired a doctorate from the University of Valencia, in the meantime working on paints at the family paint factory, Industrias Quimicas Inesba. In 1988, on reading a newspaper article about a local hospital, she started tinkering with pest control ideas, patenting her microcapsule technology in 1996. A Bolivian doctor visiting Valencia asked her if her insecticide paint could help deal with the "vinchuca" AKA "kissing bugs", biting insects that help spread the troublesome South American parasitic infection known as "Chagas disease", discussed here in 2010. Bolivia has the highest incidence of Chagas disease of any country in the world.

Mateo had never heard of Chagas disease, but she thought her paint could do the job, and went to Bolivia in 1998 to perform a test. The test went well, and she fell in love with Bolivia along the way -- and now she spends her time shuttling back and forth between Spain and Bolivia, working with family money and grants from nonprofits to set up educational programs, as well as to paint thousands of houses in Latin America and Africa. The Bolivian health minister, worried about people living in houses that generated insecticides out of the walls, tried to shut down the paint program, but after a personal appeal by Mateo to Bolivian President Evo Morales, the effort was allowed to continue.

One of the particular benefits of the insecticide paint is that it can use a mix of three or more insecticides, each in its own set of microcapsules. Use of a single insecticide tends to produce insecticide-resistant insects, but use of a set of different insecticides means that an insect has to acquire genetic variations that can deal with all of them -- and the probability of that happening is very low. It is not simple to develop insecticide sprays with multiple components because the components tend to interact, potentially neutralizing each other. The microcapsules also minimize the quantities of insecticides needed.

Mateo's work has had to struggle against systemic obstacles. One of the problems is that her approach to disease control is somewhat indirect and unobvious, and so tends to be overlooked. She says: "We spend all this time talking about medicines and diseases when the primary problem for about half the planet is that their homes are sick."

Partly, however, it's her own fault, since she doesn't like dealing with big bureaucracies, in particular seeing big corporations as malign. Mateo's adversarial stance has helped prevent her from obtaining the blessing of the World Health Organization's Pesticide Evaluation Scheme (WHOPES), an endorsement taken very seriously by public health authorities. In fact, it was the lack of WHOPES endorsement that led to her political problems in Bolivia; now the Bolivian government is acting as a sponsor to obtain WHOPES approval for the paint.

* SMART PAINTS: As discussed in THE ECONOMIST ("We've Got It Covered", 3 March 2012), people are figuring out a wide range of applications of carbon nanotubes. For example, researchers at the University of Strathclyde in the UK have developed a "smart paint", based on a cement made of fly-ash residue from coal-fired power stations, sodium silicate, and sodium hydroxide, laced with carbon nanotubes.

A structure such as a bridge or wind turbine can be covered with the smart paint. The carbon nanotubes make the paint layer conductive; a network of electrodes underneath the smart paint layer sends small-scale currents through it, with the currents changing with stress or damage to the paint layer. A central server obtaining the readings from the electrode net can then obtain a continuous reading of the integrity of the structure. The scheme is still in testing, but it promises to be cheap and effective.

An article in AVIATION WEEK ("Cold Comfort" by Graham Warwick, 12 March 2012), added that Batelle, a US research lab, is experimenting with aircraft paints rendered conductive by carbon nanotubes. Although it seems plausible the paint could be used to measure stress, the purpose is to provide anti-icing, with currents run through the paint to melt off ice. The nanotube-laced paint is lightweight, easy to apply, and much more efficient in terms of power needed to get rid of ice than current electrical de-icing schemes.

COMMENT ON ARTICLE* RETHINK THE SYSTEM (5): Having figured out a reasonable protection scheme, I then consolidated all my password information in the password file. It got to be a project, since I wanted to rationalize and simplify my passwords, and that became work. No more clunky passwords; if they're not fun and easy to use, I don't want them any more.

As an extension of rationalizing my passwords I also rationalized my email addresses. I have six accounts just for myself:

I also use this last account on my telephone answering machine. I never answer the phone directly, which is no big deal since the majority of the calls I get are from spammers and scammers, but some people with real business do contact me on occasion and I hate to give them a hard time. I just say on the voicemail that they will find it easier to get to me over email, and hand out that address -- designed to be easily understood and remembered, the form being along the lines of "usa678@q.com". Nobody's taken me up on the offer yet, but hey, I've told them how best to get in touch with me, and if they don't want to, I'm off the hook: "You're hard to get hold of." "Why didn't you email?"

I have much better control over email than over the phone. I pay for my phone service, anyone making use of my phone does so as an indulgence on my part, so I get to make the rules. Incidentally, I use the same password on all my email accounts except the Paypal account, that being the one people would most want to crack.

* Having doped out a way to protect my passwords, I found I could apply the same thinking in other ways. I use command-line FTP to upload files to the websites; it works fine, I've tried FTP programs with elaborate user interfaces and found them more bother than they were worth, but it's a nuisance to have to log in, set binary mode, turn off prompting, and possibly change directories. It is possible to put all the necessary FTP commands in a file and have them executed automatically, but that means putting a password in the file, and I don't like leaving passwords around where anyone might find them if they raided my PC.

I had a brainstorm and realized that all I had to do was write a batch file that would ask me for a password, synthesize an FTP command file using it, and run FTP with that command file. On exit from FTP, the batch script would overwrite the contents of the command file and delete it. I cooked up the batch scripts with a minimum of effort, and they worked as planned.

* One of the last things I had to do was modify the spreadsheet I used to track files on the websites. As with the passwords and email accounts, it was a good chance to clean things up and streamline them, with the end result tidier than what I had before. However, it's going to be something of an ongoing task for a while to figure out what stats are most useful for me to keep.